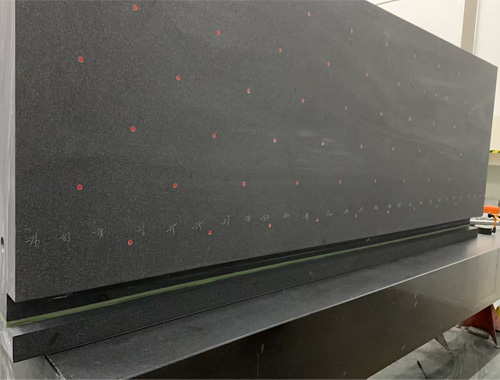

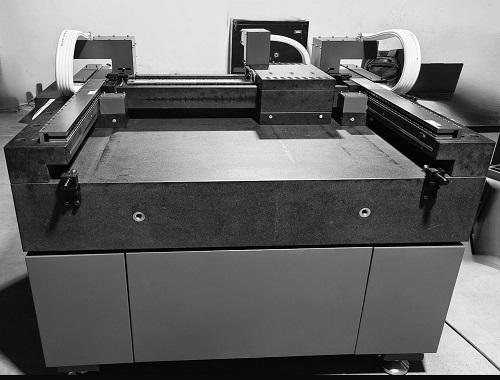

This is a 15-meter-class high-precision air-bearing granite long-stroke motion platform — a core base/guide rail component for high-end precision equipment, primarily used in large-scale precision measurement, ultra-precision machining, or aerospace applications involving large-size workpieces.

Core Features & Advantages:

Combined benefits of air bearings + granite

Natural granite serves as the base: It has a low thermal expansion coefficient (1/10 that of steel), high rigidity, and strong vibration damping. It maintains micron-level deformation even with ±2°C temperature fluctuations, while absorbing over 90% of external vibrations.

Equipped with air-bearing guides (aerostatic bearings): Compressed air is ejected through micro pores to form a micron-thick air film, enabling contactless suspension between moving components and the base. This eliminates friction, wear, and the "stick-slip effect," achieving submicron-level (0.1μm) motion accuracy with an extremely long service life.

Application scenarios for 15m ultra-long stroke

Such large-size platforms mainly support measurement/machining of large precision workpieces:

Large coordinate measuring machines (CMMs): For high-precision dimensional inspection of aerospace components (e.g., aircraft wings, engine turbine disks), high-speed rail/ship large structural parts;

Ultra-precision machining equipment: Adapted for laser processing/inspection of long-size workpieces like semiconductor wafers (large silicon wafers), photovoltaic panels, and OLED displays;

Aerospace simulation/testing: Used as a base platform for aerospace docking mechanisms and microgravity test benches, simulating frictionless motion of large-scale equipment.

Technical configuration & performance

Typically paired with linear motors/servo drives + high-resolution gratings/laser interferometers to achieve nanoscale positioning accuracy;

Modular design supports multi-axis linkage, allowing integration of probes, optical components, etc.;

Equipped with a precision air supply filtration system (0.1μm filtration accuracy) to ensure stable operation of the air-bearing system.

It is a core solution for "large size + high precision" demands in high-end manufacturing, capable of maintaining submicron-level motion stability over a 15-meter stroke.

More details please contact with me:

granite@nd-cnc.com

whatsup/skype/phone number: 0086 156 2883 0716.