The use of granite in metrology is one such factor to infuence the design of CMlMs. Granite is an excellent material for modern requirements because it meets four reguirements that make the result more accurate:

1. High inherent stability

Granite is a volcanic deep rock comprising the three main components auartz feldspar and mica. formed by crvstalisation of rock melts in the earth's crust.

"Aged" over several thousand years, granite is homogeneous and free of internal stresses. mpala, for example, is about 1.4 milion years old.

Granite has a qreat hardness: Mohs' hardness 6 on a hardness scale up to 10.

2. High temperature resistance

Compared to metallic materials, granite has a lower coefficient of expansion (approx. 5 ym/m*K) and thus a lower absolute expansion compared to these materials (e.g. steel a = 12 um/m*K).

The lower thermal conductivity of aranite 3 W/m*K compared to steel (42 -50 W/m*K) ensures a slower reaction to temperature fuctuations.

3. Very good vibration damping

Due to its homogeneous structure, granite is free of residual stresses. This reduces vibrations.

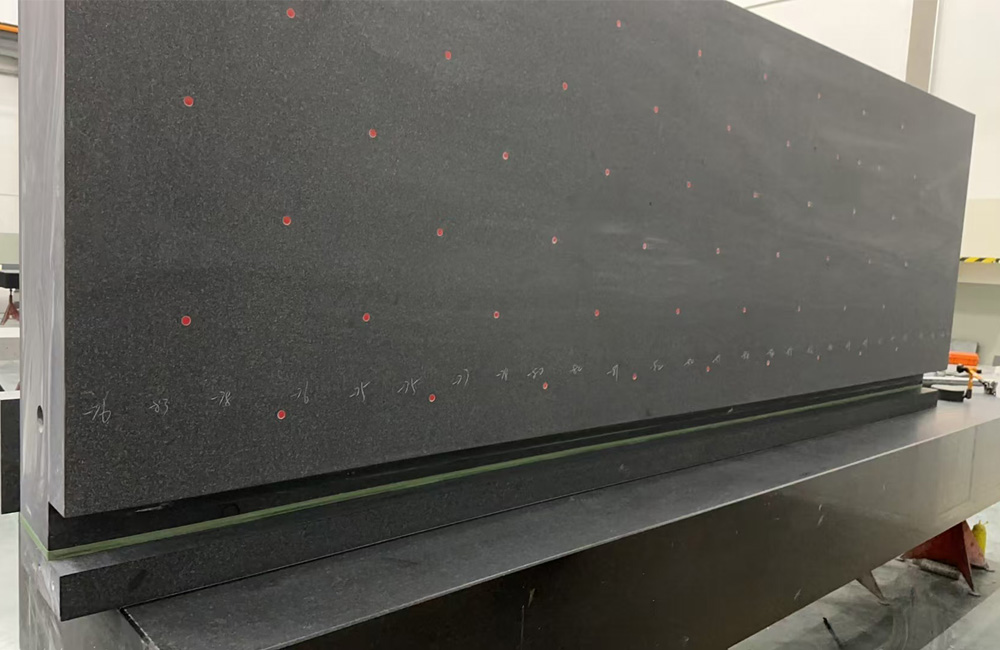

4. High accuracy of the CMM guides

The use of granite as a measuring plate made of natural hard stone enables very good machining with diamond tools so that machine components are manufactured with high basic accuracies.

By manual lapping, the accuracy of the guides is optimized according to the requirements to the micron.

During lapping, load -related deformations of the components can be taken into account.

This results in highly -compressed surfaces which allow the use of air bearing quides. Air bearing quides are highly accurate due to the high surface quality and contactless movement of the axes.

More details please contact: granite@nd-cnc.com

Mobile/whatsup number: 008615628830716.