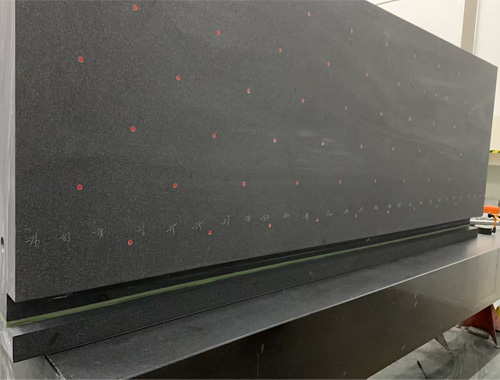

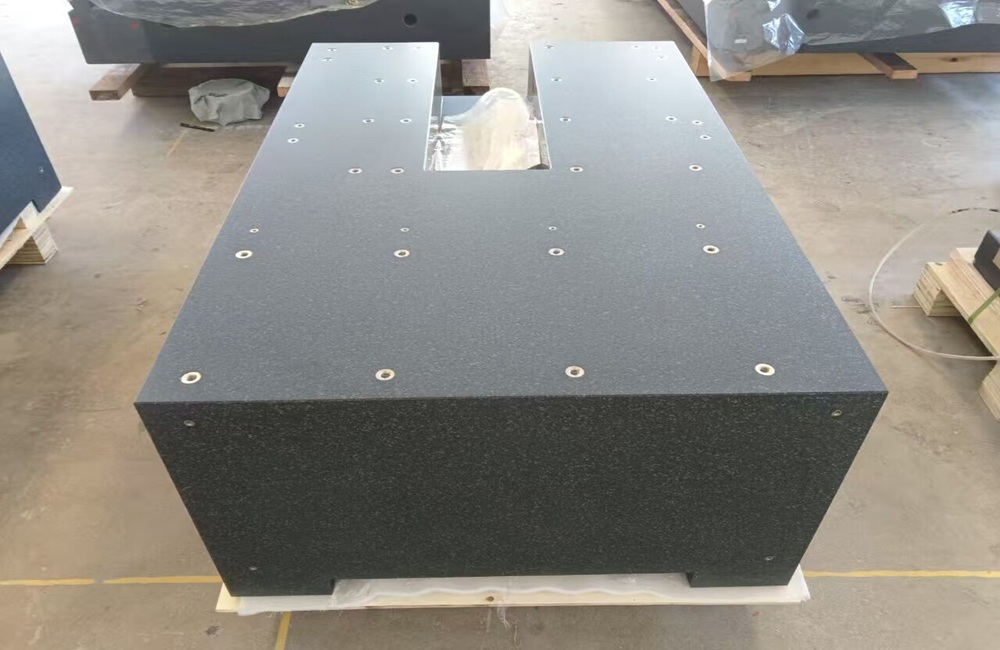

This U-shaped high-precision granite product is mainly used as the base for precision measuring and machining equipment, with typical applications including:

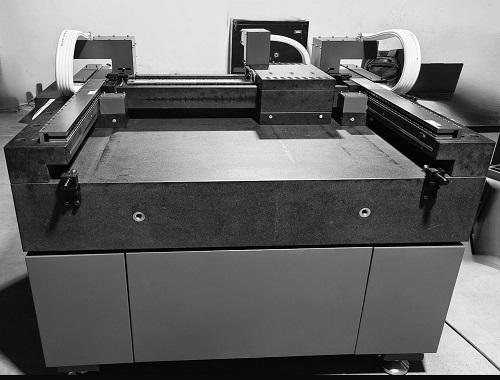

1. Base of Coordinate Measuring Machine (CMM)

Coordinate measuring machines require ultra-high stability to ensure measurement accuracy. The U-shaped structure not only provides rigid support, but also reserves operational space for the measuring probe and workpiece, making it one of the core bases for such equipment.

2. Base of Laser Processing/Testing Equipment

Equipment such as laser cutting machines and laser interferometers are highly sensitive to vibration and thermal deformation. Granite features a low coefficient of thermal expansion and excellent damping properties (its vibration absorption capacity is 3–5 times that of cast iron), which can effectively reduce errors during equipment operation. The U-shaped structure is suitable for the layout requirements of laser optical paths or workpieces.

3. Base of Semiconductor Equipment

Semiconductor lithography and wafer inspection equipment need to maintain submicron-level precision in clean rooms. Granite’s non-static, corrosion-resistant and thermally stable properties (its coefficient of thermal expansion is only 1/10 that of steel) make it an ideal base for such high-precision equipment. The U-shaped structure can match the movement space of wafer transfer systems or robotic arms.

4. Base of Precision Machine Tools/Automation Equipment

The core stations of some high-precision grinders, milling machines or automated assembly lines adopt such granite bases to improve machining and assembly accuracy. The U-shaped structure can accommodate components such as worktables and guide rails, while the wear resistance and stability of granite extend the service life of the equipment.

Its core advantages lie in low thermal deformation, high vibration absorption and long-term dimensional stability, which can provide a "datum-level" supporting foundation for high-precision equipment.

If you need more details, please contact with me:

Email: sofia@nd-cnc.com

Whatsup/Skype/phone number: 0086 156 2883 0716.