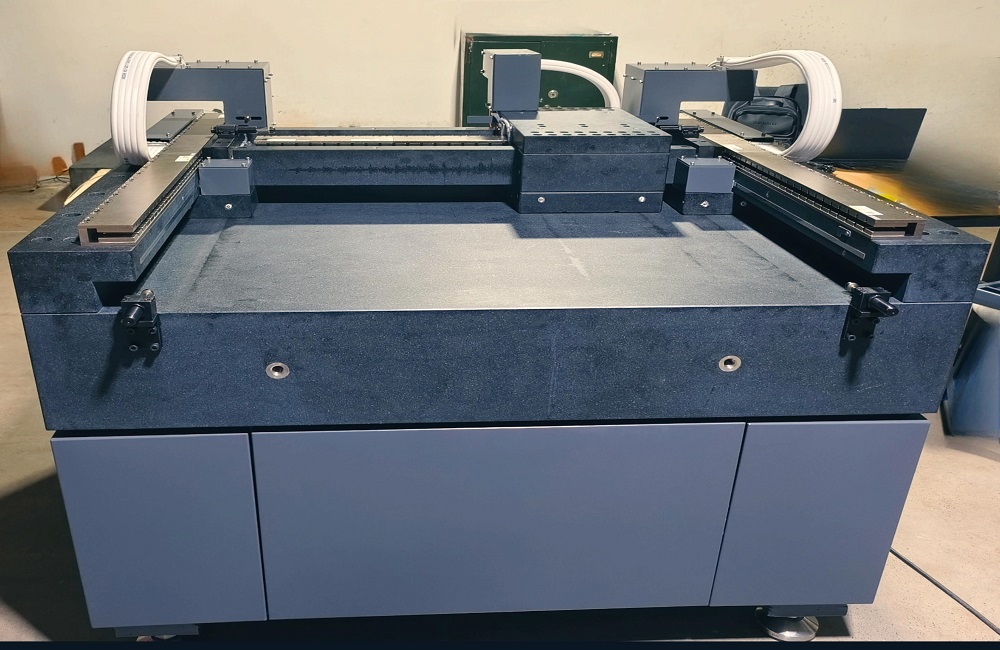

A Super L-size precision air bearing gantry stage is a high-performance motion system designed for ultra-precise positioning in applications requiring nanometer-level accuracy, minimal friction, and high stability.

These stages are commonly used in semiconductor manufacturing, photonics, metrology, and advanced research.

Key Features:

1. Air Bearings

Frictionless Motion: Uses a thin film of pressurized air to eliminate mechanical contact, reducing wear and enabling smooth, vibration-free movement.

Nanometer Precision: Achieves sub-micron to nanometer-level positioning accuracy and repeatability.

Zero Backlash: Ideal for high-precision scanning and alignment tasks.

2.Gantry Design (L-Size Configuration)

Large travel range (typically 500mm to several meters in X and Y axes).

Dual-drive synchronization for high rigidity and precision in gantry motion.

Suitable for handling oversized workpieces or multiple processes.

3.High Precision & Stability

Sub-micron to nanometer positioning accuracy with laser interferometer or high-resolution encoder feedback.

Low thermal expansion materials (e.g., granite, or composite structures) for thermal stability.

4.Advanced Motion Control

Direct-drive linear motors or high-precision servo motors for smooth acceleration/deceleration.

Active vibration damping and dynamic error correction.

5.Modular & Customizable

Can integrate rotary stages, Z-axis lift, or multi-axis configurations.

Compatible with vacuum environments (if required).

Applications:

Semiconductor Lithography & Inspection

Flat Panel Display (FPD) Manufacturing

Precision Metrology & Optical Alignment

Laser Processing & Micromachining

Advanced Research (e.g., Quantum Tech, Photonics)